Aspect of optimised precipitation strategies

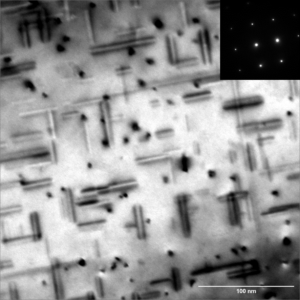

TEM bright field image of the [0 0 1] zone with corresponding selected area diffraction pattern showing β’’-precipitates in alloy 6060.

Due to the properties of aluminium and the associated lightweight potential, it is increasingly used in the automotive sector. Extrusion profiles made of Al-Mg-Si alloys are often used for safety relevant components that protect the passenger compartment in the event of a crash. Ensuring high strength with sufficient ductility in the application at the same time is a major challenge. In addition, the high degrees of forming during extrusion must be taken into account. In order to better meet this requirement, it is essential to understand the precipitation sequences of hardenable Al alloys.

The initial clustering forms the basic stone of excretory hardening. In the course of the project, this will be investigated and understood in more detail using atom probe tomography, transmission electron microscope and indirect methods (hardness, conductivity, etc.). Furthermore, the influence of trace elements as well as cold / hot storage on the precipitation sequence will be considered.