Quality assured scalability of the WAAM process for the fabrication of aeronautic structural elements (QuSAM)

Subject area:

Light Metals & Mechanical Testing

Responsible Employees:

Prof. Dr.-Ing. Heinz Werner Höppel

Annalena Meermeier (M. Sc.)

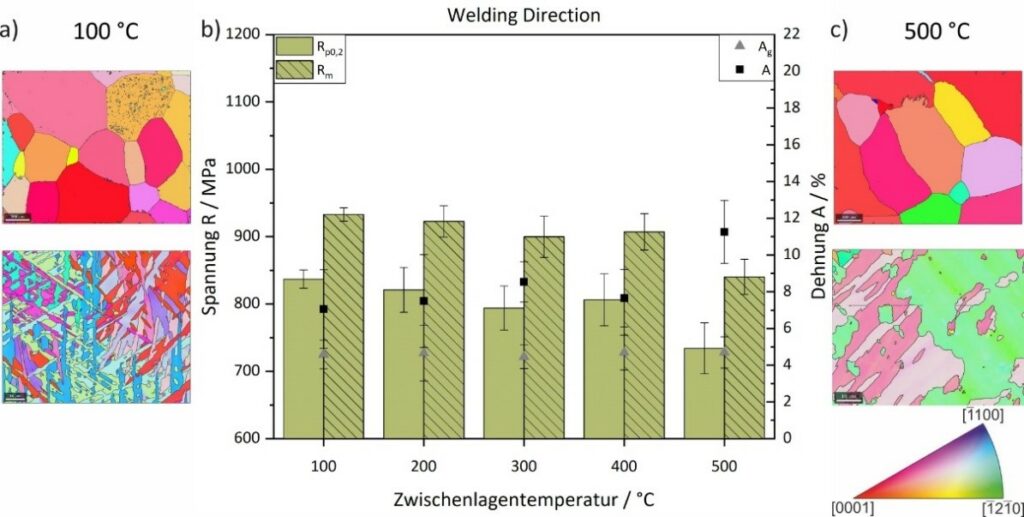

Influence of interlayer temperature on mechanical properties determined in tensile tests. EBSD images of the microstructure of samples with an interlayer temperature of a) 100 °C and c) 500 °C show reconstructed primary β-grains at the top and IPF mappings at the bottom.

TiAl6V4 (Ti-64) is one of the most commonly used alloys in aerospace industry. Nowadays, structural parts are milled from solid blocks. This results in a degree of machining of up to 96 %. Thus, aerospace industry is in need of an advanced technology, which improves the ecological footprint and the costs for structural parts. This becomes even more important as the market demand is increasing steadily.

A promising possibility for a resource efficient production is wire and arc additive manufacturing (WAAM). With this technique, it is feasible to decrease the lead-time, save energy and reduce the material loss to 7-20 %. Unlike SLM or EBM processes it is feasible to produce at significantly higher application rates and higher volumes. Another advantage is the saving of further processing steps, like roughing and HIPing.

In the preceeding project REGULUS, the influence of basic process parameters, as for example the welding speed and the wire feed speed, were investigated. The interlayer temperature has proven to be an important factor influencing the microstructure and mechanical properties. The goal of the research project QuSAM is to apply the findings gained in REGULUS to large-volume parts with complex geometries. In cooperation with the Technical University Munich and the companies HEGGEMANN AG and verlinked GmbH, test specimens with different geometries are fabricated using varying process parameters. The scalability will be examined through quasi-static and cyclic tests, as well as through the analysis of the resulting microstructure by means of SEM, EBSD, TEM and APT. To achieve the project’s goals a digital twin of the process will be built up for quality control and optimization.

The research project QuSAM is funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK) (grant number 20Q2121F).