Additively manufactured in-situ Composites

Subject area:

High Temperature Materials

Responsible Employees:

PD Dr. Steffen Neumeier

Andreas Förner (M. Sc.)

Jan Vollhüter (M. Sc.)

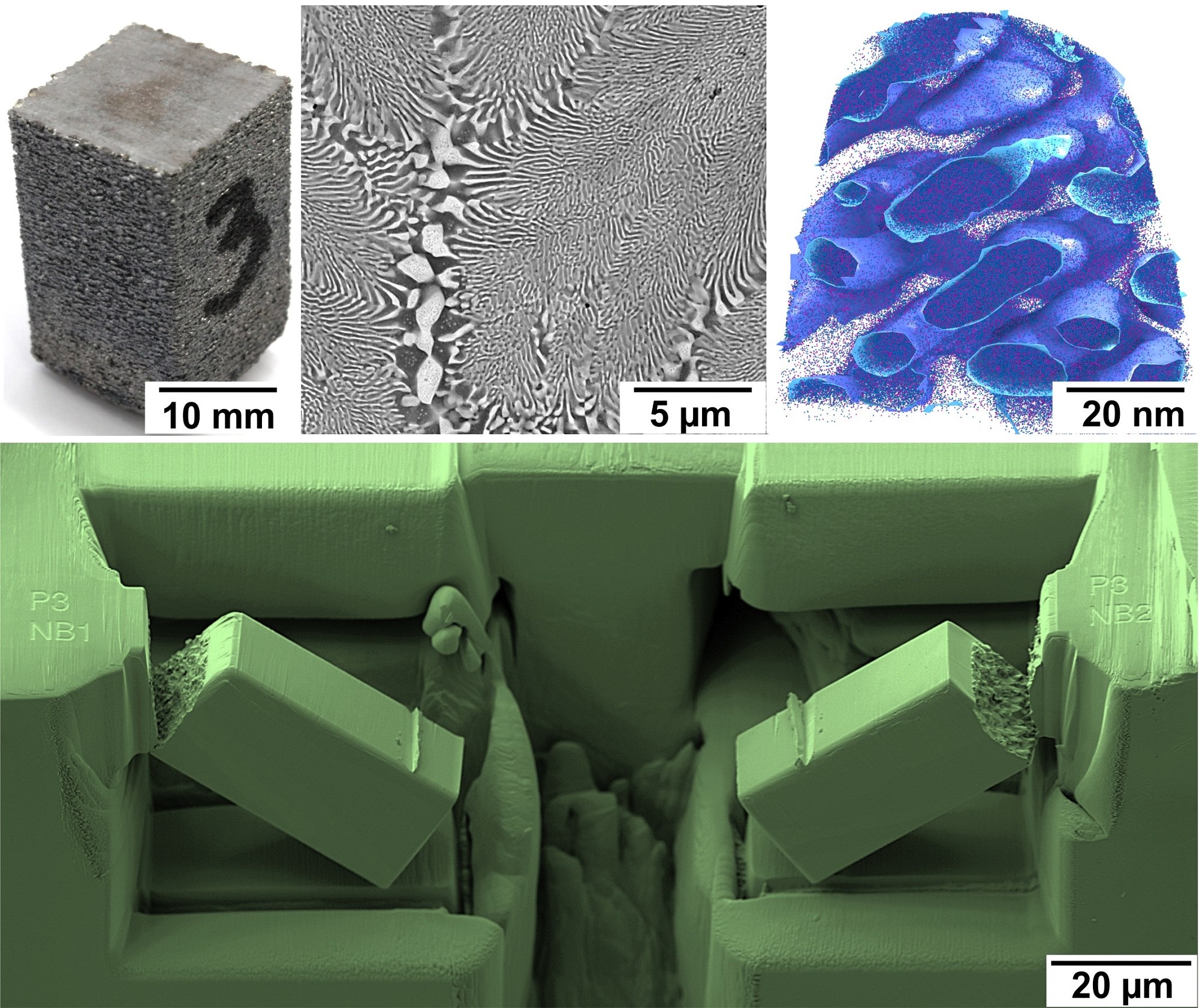

Up: Nanostructured microstructure of additively manufacured NiAl-(Cr,Mo).

Down: Testing the fracture toughness of additively manufacured NiAl-(Cr,Mo).

The in-situ composites NiAl-(Cr,Mo) and Nb-Si-Cr are promising high temperature materials. The intermetallic-based eutectic materials exhibit low density, high melting point, and offer good heat conductivity and oxidation resistance. However, a low room temperature fracture toughness and insufficient creep strength at high temperatures have both been limiting their application. This project seeks for strategies to improve those disadvantages and investigates the potential of this material group.

Additive manufacturing is a promising approach, since high cooling rates present in selective electron beam melting enable the creation of a nanostructured material. The presence of many small phases and the adjustment of a columnar textured cellular structure enables both, high cracking resistance at room temperature and sufficient high temperature creep behavior. Microstructural characterization and investigation of the present deformation mechanisms is the key to understand the improved material behavior. High resolution electron microscopy and atom probe tomography are valuable instruments in characterizing nanostructured intermetallics.