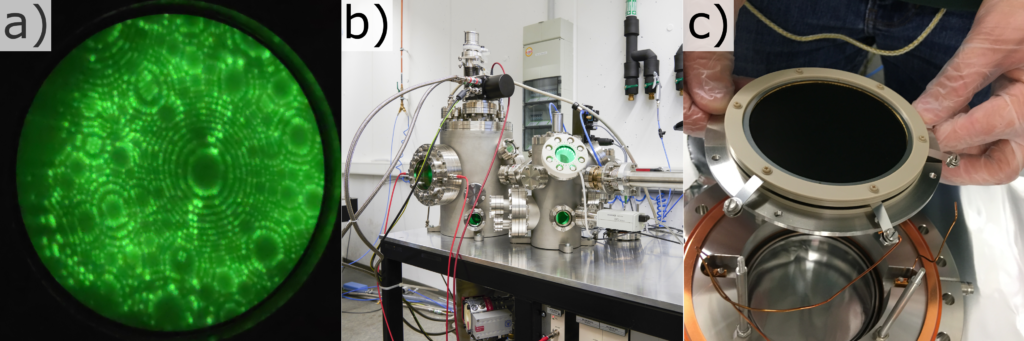

The field ion microscope [1] allows the imaging of a tip-shaped probe surface on a detector screen at atomic resolution. To accomplish this, a positive voltage is applied to a needle shaped sample in the presence of a residual pressure of a noble gas (He, Ne, Ar …) in high vacuum. Gas atoms ionize at sites of increased electric fields, namely at lattice plane steps and protruding atoms at edge positions. These field desorbed ions are accelerated along the tip’s electric field towards position sensitive detector. The flight path can be described by a point projection. A typical FIM image of a tungsten sample can be seen in a). Rings represent individual atomic plane steps and bright spots represent individual atoms.

The FIM at the institute (Fig. B) was developed and built in the working group of Prof. Peter Felfer from a design by Dr. Patrick Stender from the Institute for Materials Science, University of Stuttgart.

Key features of this instrument, that exceed the very basic functions of FIM, are:

- The voltage pulser enables automated 3D FIM analysis [2].

- A titanium sublimation pump with cryo-shielding is connected in addition to a turbo pump in the main chamber. Additionally, there is a valve between the turbo pump and the main chamber. This enables 1) FIM operating at continuous gas flow while the turbo pump is pumping, or 2) discontinuous gas supply, by shutting off the turbo pump while titanium sublimation pump and cryo-shielding are running.

- The flexible design allows for adapting to specialized scientific questions. Additional components can be connected to the free vacuum ports. Potential upgrades are prepared for in the current set-up. For instance, the sample stage of the buffer chamber can be cooled for cryotransfer experiments (analogous to [3]) or the FIM can be upgraded into an atom probe.

Further technical details about the system are:

The vacuum system consists of three chambers: a) a load lock for quick sample loading, b) a buffer chamber for storing samples and c) the analysis chamber. All chambers are pumped by turbo molecular pumps (Pfeiffer Vacuum). The probe is cooled by a cryo head (Oxford Cryosystems) and the temperature can be regulated by counter heating. The detector with a diameter of 7.7 cm (picture c) is a P43 phosphor screen with microchannel plate amplification.

[1] E.W. Müller, Das Feldionenmikroskop, Z. Für Phys. 131 (1951) 136–142. https://doi.org/10.1007/BF01329651.

[2] M. Dagan, B. Gault, G. Smith, P. Bagot, M. Moody, Automated atom-by-atom three-dimensional (3D) reconstruction of field ion microscopy data, Microsc. Microanal. 23 (2017) 255–268. https://doi.org/10.1017/S1431927617000277.

[3] S.S.A. Gerstl, R. Wepf, Methods in creating, transferring, & measuring cryogenic samples for APT, Microsc. Microanal. 21 (2015) 517–518. https://doi.org/10.1017/S1431927615003384.

Responsible employees:

Department of Materials Science and EngineeringProf. Dr. Peter Felfer

Chair of General Materials Properties

Mehrpad Monajem, M. Sc.

Department of Materials Science and Engineering

Chair of General Materials Properties

- Phone number: +49 9131 85-25449

- Email: mehrpad.monajem@fau.de