Machine Learning-aided Prediction of Material Properties from Nanoindentation

Due to the current development of different machine learning models as well as the possibility of additive manufacturing, new material systems are being researched and synthesized ever more quickly and efficiently. However, whether these systems are also used often depends on suitable mechanical properties, which also should be determined in the shortest possible time. These include the stress-strain curve, fracture toughness and fatigue life. Unfortunately, the determination of these – in particular fatigue properties – is extremely time-consuming. Nanoindentation, on the other hand, offers the advantage of determining several material properties in a relatively short time. These include hardness and elastic modulus as well as, for example, strain rate sensitivity, wear resistance or the creep properties of a material. However, these properties are unfortunately not sufficient for the reliable development of high-performance components.

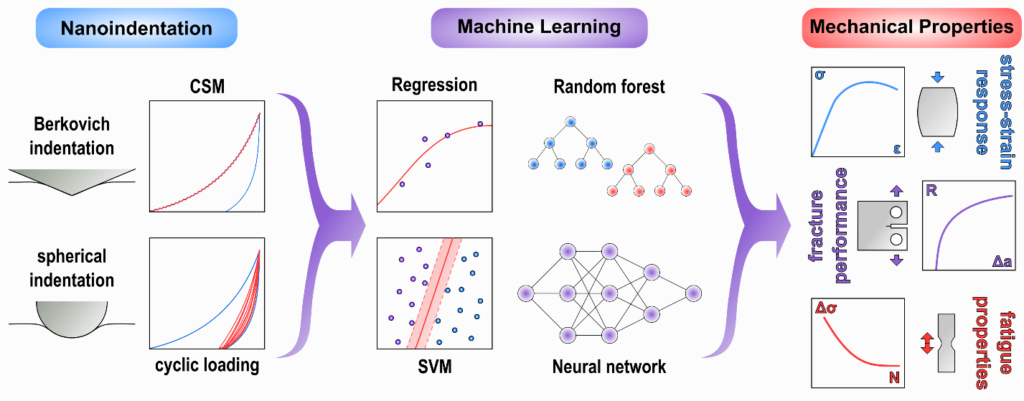

The aim of this project is therefore to predict the necessary mechanical material properties from the results of nanoindentation using different models of mechanical learning (ML). Various regression models, support vector machines (SVM) and also artificial neural networks (ANNs) will be used for this purpose. In the course of the project, a multitude of different metallic systems will be characterized using both nanoindentation and mechanical testing methods, and the largest possible database will be built with this data. This will then serve as input for the ML model, so that a high degree of precision can be achieved in the prediction of the essential mechanical parameters.