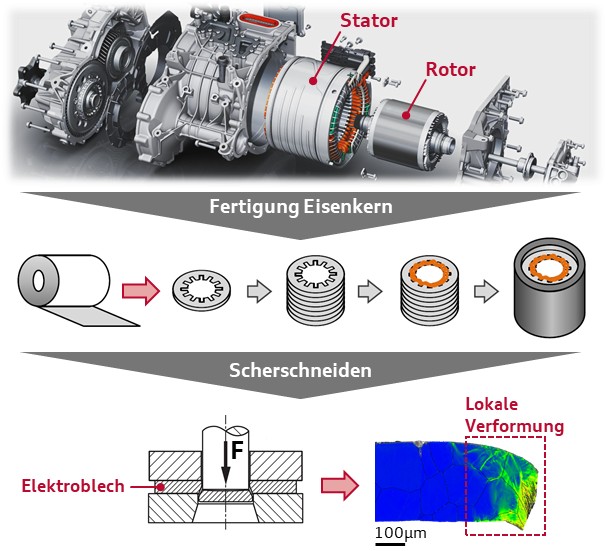

Investigation of the local degradation of magnetic properties of nonoriented electrical steel by shear cutting, for use in automotive electric motors

Due to its soft magnetic properties, electrical steel is particularly well suited for guiding magnetic fields. For this reason, it forms the main material of electric traction machines in a stacked form as a rotor and stator. The manufacturing process from the sheet metal coil to the electric machine significantly influences the magnetic properties. The focus of this project is the manufacturing step “shear cutting”. This gives the sheet the final rotor or stator geometry. Because of the local deformation at the cutting edges, the magnetic properties of the sheet deteriorate.

The aim of the project is to identify /quantify magnetic losses due to shear cutting depending on the sheet metal used, in order to create the possibility to take the processing influence in the motor design into account in detail.